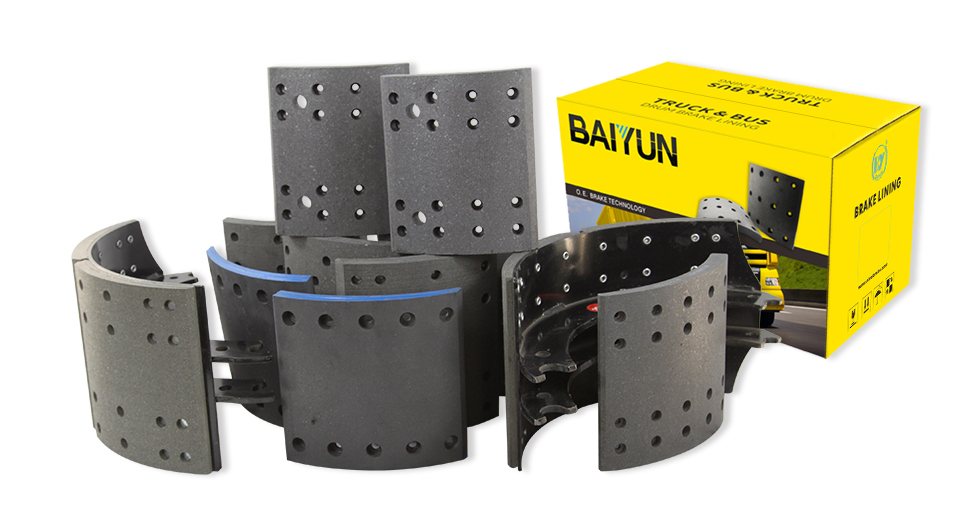

As the leading manufacturing of brake pads and linings to the commercial vehicle market, BAIYUN works closely with the fleets and heavy duty truck and bus manufacturers to engineer a range of friction materials that are specific to individual vehicles and their braking systems, BAIYUN makes a large number of practical road tests with them and provides the optimum braking solution. Up to now, BAIYUN has over 280 models drum brake linings for commercial vehicles including trucks, trailers,buses and coaches. BAIYUN has become an important OEM partner for many famous brands like YUTONG, DONGFENG, FOTON, SHACMAN, HOWO, FAW etc.

| Brand Name | BAIYUN |

| Product name | C.V. Brake Lining Pads |

| Place of Origin | China |

| Condition | New |

| OEM | Available |

| Purpose | For replace/repair |

| Color | Customers' Requirements |

| Packing | Customized Packing |

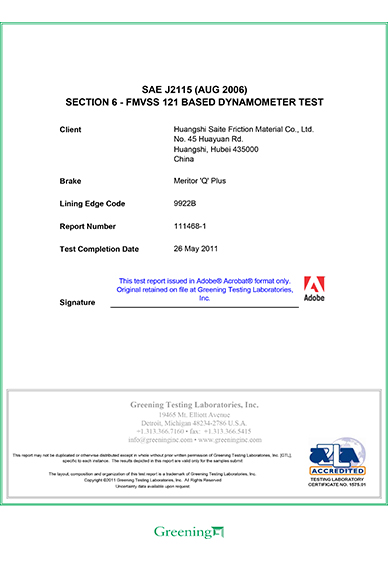

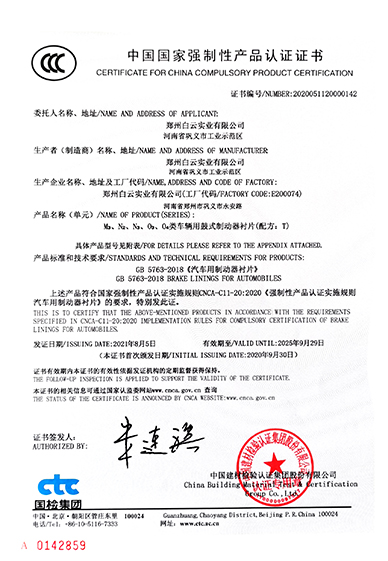

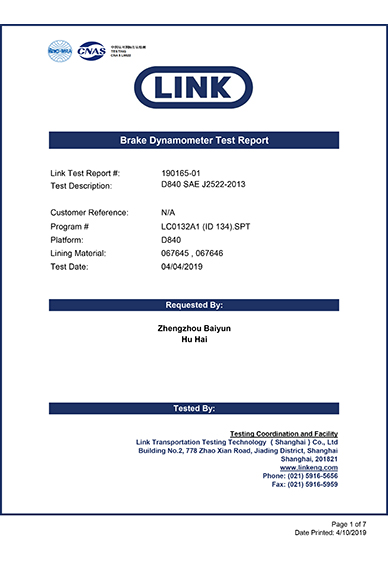

| Certification | IATF16949 ISO9001 E-MARK EAC CCC DOT |

| OE NO. | WG9231342069, 3552-00753, 3552-00676, 3552-01235, 3552-01010 0300099476, 0309226010, 0309226260, 0309226320, 0309226450, 0309226560, etc. |

| WVA NO. | 19032, 19094, 19369, 19370, 19486, 19487, 19488, 19579, 19580, 19581, 19582, 19036, 19037, 19931, 19932, 19933, 19938, 19939, 19940, 19245, 19782, 19246, etc. |

| Warranty | In warehouse warranty: 10years ; Working life warranty: 100,000kms |

| Reference NO. | CVP020, 12-5278, FCV1313, FCV134515, 4551, 4707, 4709, CA/32, CA/33, WG9231342069 etc. |

Durable and long-lasting.

Reduces braking noise, enhancing driving comfort.

Excellent braking performance for safety.

Various models of cars, SUVs, and commercial vehicles.

High-performance.

Customizable to client specifications.

| Friction Coefficient | u0.38 - 0.42 |

| Shear Strength | 4 N/mm2 |

| Density | 2.6-3.2 g/cm3 |

| Compressibility@25°C | <2% |

| Compressibility@400°C | <5% |

| Maximum continuous temperature | 400°C |

| Maximum short duration temperature | 700°C |

BAIYUN formulas are specifically designed to meet today’s O.E. and automotive aftermarket performance standards and demands, including new stopping distance regulations, as well as the demands of heavy duty applications.

Each brake pad is specially engineered for its purpose and vehicle, with some products featuring up to 45 raw materials to create the perfect formula.

1.There are 18 different brake friction formulations for drum brake linings of commercial vehicles in our portfolio. We design and engineer each friction formulation specifically for the vehicle’s requirements to deliver optimum performance, comfort and longevity.

2.Adopt top core raw materials, and cooperate with famous brand in their respective raw materials like: American Dupond aramid fiber, Holland DSM Mineral fiber, Japan Otsuka PTW and Shengquan phenolic resin etc.

3.Each formulation has passed up to 2,000 hours of dynamo-meter testing and up to 300,000 kilometers of testing, intensive NVH testing (Noise, Vibration, Harshness)and comfort engineering

4.Each brake lining is pushed to the extremes by our technical team before it is released into the market.

| Branches of BAIYUN Group | 7 |

| Years in Business | Over 47 years |

| Staff | 758 |

| Registered Capital | Over 20,000,000 USD |

| Quality Inspectors | 52 |

| Foreign Trade Service Personnel | 30 |

| Product Equipment Quantity | 865 |

| Factory Area | 150,000m² |

We understand you might have some questions before cooperation or placing an order. Here are some common inquiries and their answers:

Yes, free samples are offered, but the freight cost is borne by you.

Minimum order quantity is 100 sets per item, 2,000 sets per total order.

Payment term: TT, 30% deposit before production, 70% balance before shipment. FOB Qingdao.

7 working days for samples, 45 days for mass production.

We usually ship by DHL, UPS, FedEx, or TNT for samples. Air and sea shipping are also available, typically taking 7 days to arrive.

We will prepare artwork for visual confirmation, produce a real sample for your second confirmation, and then proceed to mass production after your approval.

We can send you free samples. Our production matches the samples.

We will provide equal quantity replacements at no extra cost.

We only accept wholesale and custom orders, no retail. Contact us for wholesale quotes.

Your inquiry will be replied within 24 hours.