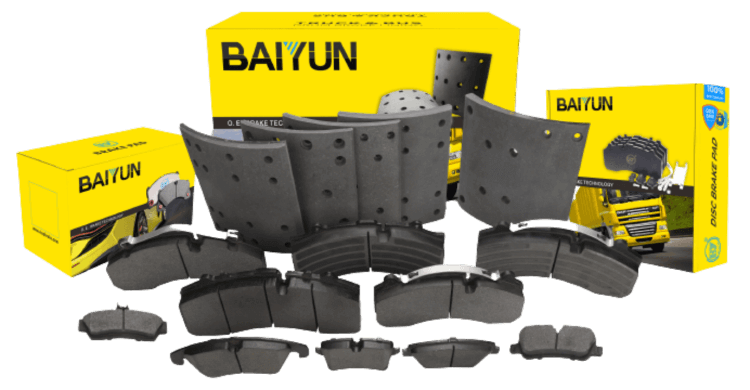

Over 120 models disc brake pads for commercial vehicles including trucks, trailers,buses and coaches.

Over 280 models drum brake linings for commercial vehicles including trucks, trailers,buses and coaches

Over 1500 models brake pads for passenger car including light vehicles, SUV, MPV,ORV

Over 1500 models brake pads for passenger car including light vehicles, SUV, MPV,ORV

As one of the leading manufacturing in brake technology, Baiyun brakes utilizing cutting-edge brake technology are precision engineered to offer maximum safety, performance and comfort. This uncompromising approach have been insisted over 45 years.

READ MORE

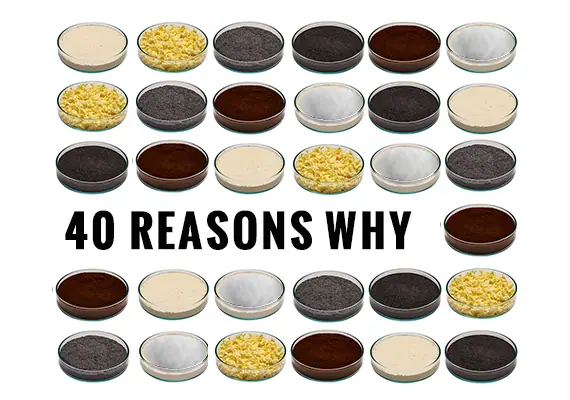

Each brake pad is specially engineered for its purpose and vehicle, with some products featuring up to 40 raw materials to create the perfect formula.

Expert attention to design and detail ensures the ideal balance between performance, comfort and longevity. Providing reassurance and confidence for your customers when they choose Baiyun.

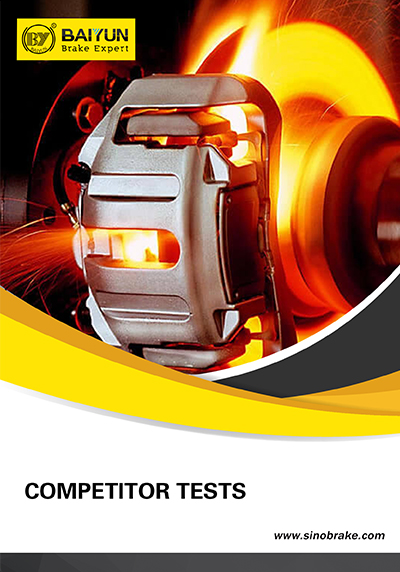

WE ARE ALWAYS PROVING OUR QUALITY. WE ASSESS OUR BRAKE PRODUCT IN THE MOST EXTREME CONDITIONS TO PUT THEM TO THE TEST. ENVIRONMENTS LIKE CONTINUOUS DOWNHILL IN THE MOUNTAINS OF WESTERN CHINA, WHERE THE TEMPERATURE ON THE DISCS CAN REACH UP TO 700 DEGREES, PROVE THAT WE PERFORM BETTER THAN OUR COMPETITORS EVERY TIME.

When you use BAIYUN brake pads, not only do you need to use less force on the brake pedal for the same strong and consistent performance, but our pads wear at a slower rate than our competitors.

SMALL BUT MIGHTY. OUR FRICTION HAS THE ABILITY TO STOP A 40-TONNE TRUCK IN A 3 SECONDS EMERGENCY STOP WHICH REQUIRES A BRAKING POWER OF 3,200KW. AN UNBELIEVABLY HIGH STRESS FACTOR FOR THE RATHER SMALL BRAKE COMPONENT.

Safety is paramount, we never compromise on quality. That is why we take up to 5 years to develop the perfect friction material specifically for the vehicle, its braking system and purpose.

AS TOP 10 LEADING CHINA MANUFACTURER WE HAVE ONE PHILOSOPHY — TO PROVIDE THE PERFECT AND SUITABLE BRAKE SOLUTION TO THE CLIENTS AND MEET THE VARIOUS APPLICATIONS.

We do not believe in a one-size-fits-all brake pad, instead we go to great lengths to develop a bespoke solution that matches the vehicle’s exact requirements; even if this causes higher complexities, time or investment.

OVER 45 YEARS OF HISTORY, BAIYUN HAS BEEN A DRIVING FORCE OF BRAKING TECHNOLOGY SINCE THE VERY BEGINNINGS OF THE CHINESE AUTOMOTIVE INDUSTRY.

We were first for ceramic braking, first with lightweight pads for commercial vehicles in the aftermarket, and first-fit on the original DONGFENG, SHACMAN Heavy truck and YUTONG bus . We don’t just move with the times, we change the times.

AS LEADING EXPERTS IN BRAKE TECHNOLOGY WE BELIEVE IN SPECIFICALLY DESIGNED SOLUTIONS. THIS IS WHY WE HAVE 75 DIFFERENT BRAKE FRICTION FORMULATIONS IN OUR PORTFOLIO.

We design and engineer each friction formulation specifically for the vehicle’s requirements to deliver optimum performance, comfort and longevity.

EVERY YEAR, 4200K SETS HIGH QUALITY BRAKE PADS ARE DELIVERED FROM BAIYUN WAREHOUSES.

BAIYUN offers larger portfolios of braking products for modern vehicles. We go further than anyone to deliver exactly the right product, at precisely the right time, for every customer.

OUR BRAKE PADS ARE NOT A ONE SIZE FITS ALL SOLUTION. THEY ARE AS DIFFERENT AS THE VEHICLES WE PRODUCE THEM FOR.

THIS IS WHY WE HAVE INVESTED IN FIVE DIFFERENT MANUFACTURING PROCESSES AND UNIQUE EXPERT EQUIPMENT.

By doing this, we ensure that all of our products are the best possible solution for every vehicle and its system.

OUR EXPERT ENGINEERS CONTINUE TO DEVELOP SPECIALIST BRAKE PADS FOR THE NEW ERA OF MOBILITY. BAIYUN BRAKE PRODUCT COVER MORE THAN 80 BRAND VEHICLES AND AXLES.

Today Baiyun offers the widest range of brake friction products for electric and hybrid vehicles in the aftermarket.

AS A GLOBAL MANUFACTURER OF BRAKE PADS AND LININGS, WE PRODUCE 12K FRICTION PRODUCTS PER DAY.

By designing, developing and testing our products in house, we have complete control over the manufacturing process to guarantee consistent high quality, all created and approved to 100% BAIYUN Friction standards.

AS PART OF OUR EXTENSIVE R&D FOR EACH BRAKE PAD, OUR TECHNICAL TEAM SPENDS OVER 10,000 HOURS EACH YEAR ON ROAD TESTING NEW FRICTION FORMULAS.

In addition to our dynamo-meter testing, we push our friction to the extremes in real life situations and environments to ensure the pad consistently performs well in all conditions.

OUR EXPERTS TWENTY PERSENT OF BAIYUN TOTAL EMPLOYEES DEDICATED TO DESIGNING, MANUFACTURING AND TESTING SOME OF THE MOST ADVANCED BRAKING SOLUTIONS ON THE MARKET. EACH YEAR WE PUT 20% OF ANNUAL SALES REVENUE SPEND ON RESEARCH AND DEVELOPMENT OF MATERIALS AND PRODUCTS.

Our strong team of professionals, committed to delivering excellence, guarantees our position as leading brake friction manufacturers.

Each BAIYUN brake pad is pushed to the extremes by our technical team before it is released into the market.

From 300,000 kilometers on the road and on our test track in the fleet of vehicles to 2,000 hours on BAIYUN dynamo-meters, we ensure premium performance and maximum safety is reached each and every time.

Baiyun’s processes are certified by ISO9001:2008 and IATF16949:2016.

Technical Tips &Trouble Tracers, Celebrity mechanic takes you through step-by-step technical guides

BAIYUN technical tips can help you slove some of the most problematic vehicle issues.

The testing data of brake pads help BAIYUN brake pads beat the performance of major aftermarket competitors.

Let the BAIYUN trouble tracers help you quickly identify common problems with your brake linings to keep you safer on the road.